Weight Reduction Through Structural Foam Injection Moulding

16.09.2019

With ease to the best and most cost-efficient result.

With ease to the best and most cost-efficient result.

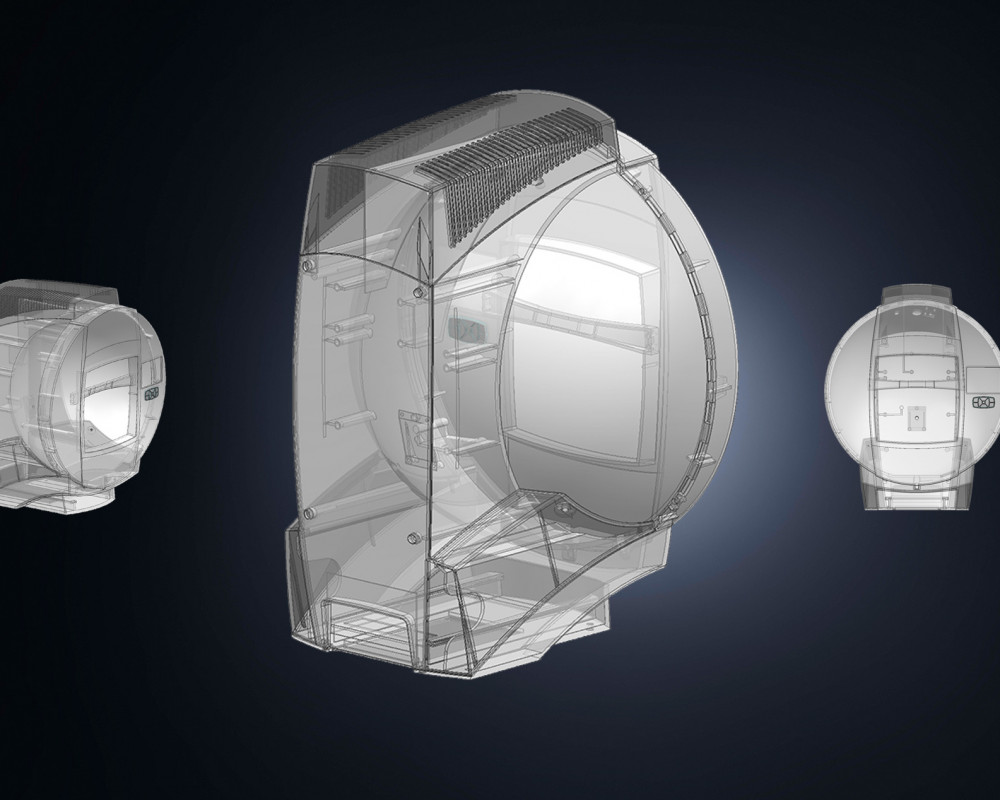

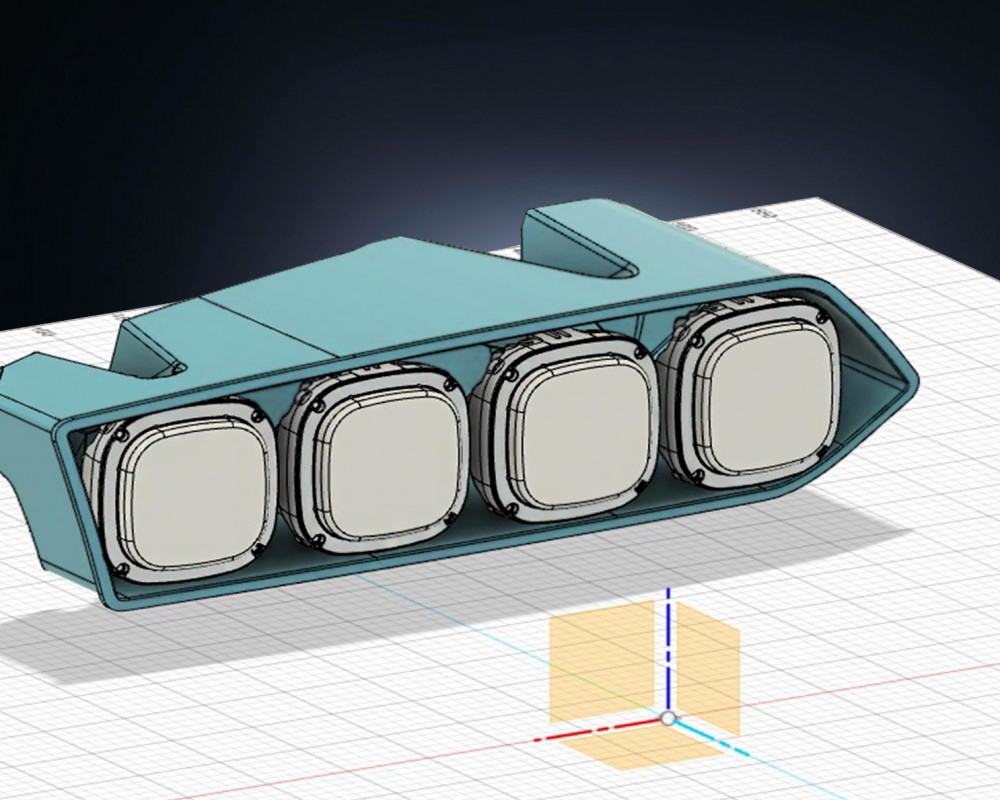

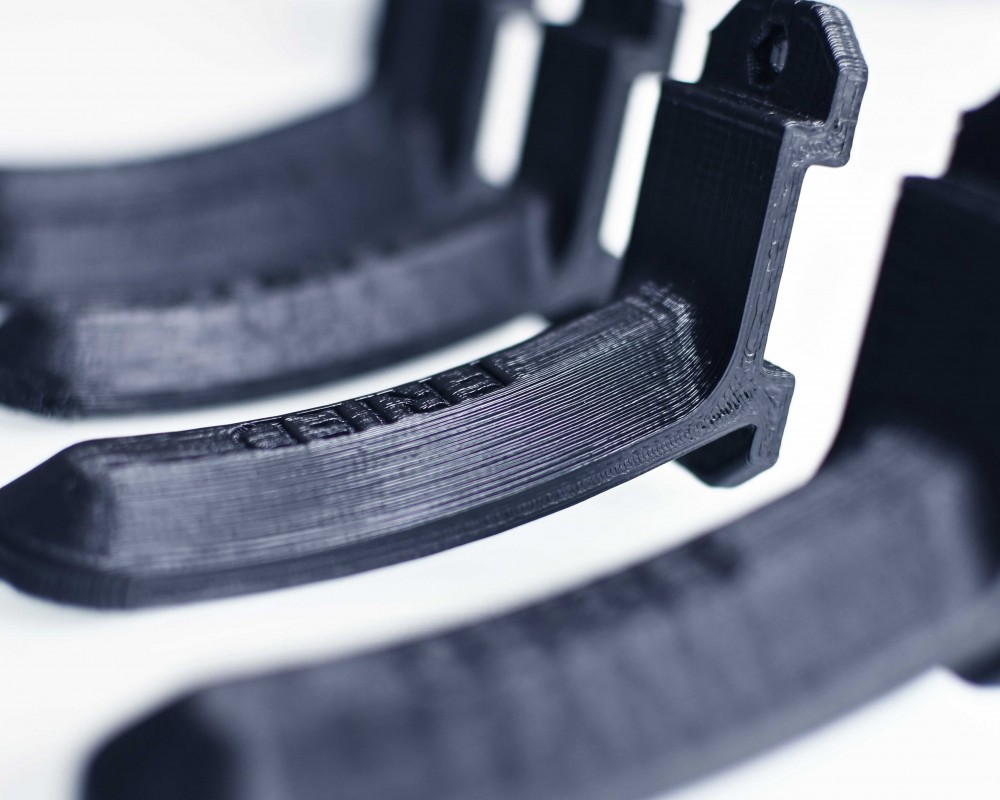

Reduce weight and costs with structural foam moulding at Fried

As the product and industry requirements increase, so do the demands for the materials. So it is not surprising that in many industries metal is replaced by plastic. However, the advantages of metal components, namely stability and strength, cannot be replaced by classical injection moulding.

Here, the structural foam process combines the advantages of metal casting with those of structural foam moulding. The components achieve high rigidity despite of the lower weight. This is achieved by high wall thickness and the foam structure which is achieved through the structural foam process. Thus can be achieved precision and stability in daily use, a high degree of design freedom and cost-efficient production.

More