Fried Plastics Engineering – Key Advantages

- Development and production of technical precision parts and plastic assemblies

- Tool design and manufacturing

- From the idea of the product to the series production

- From low to high quantities

- A variety of technical procedures to choose from

- Design, stability and surface quality

- Environmentally friendly use of recycled plastic

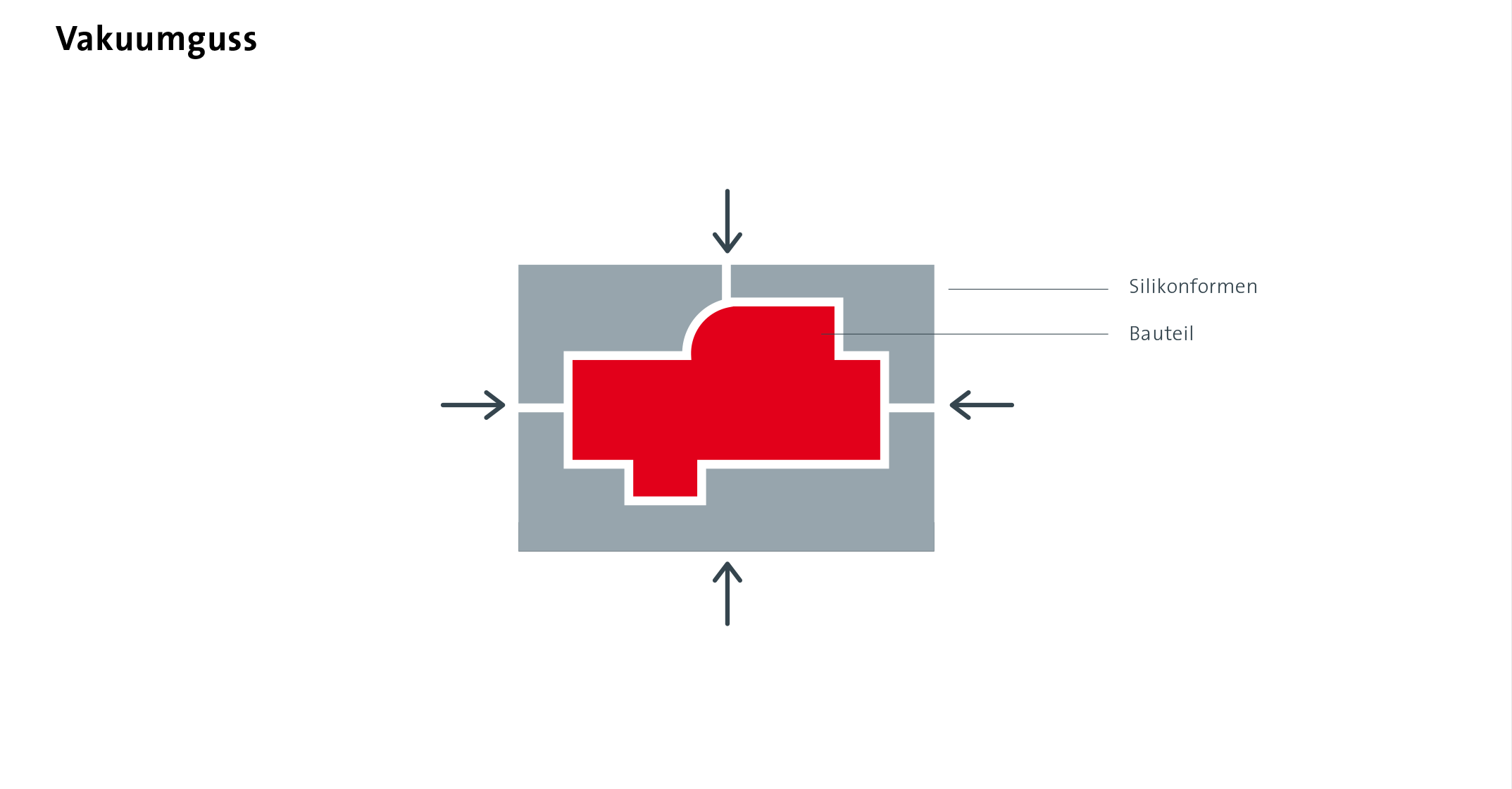

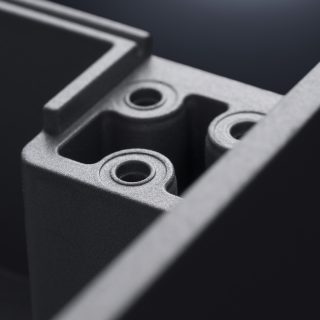

Manufacturing Prototypes and Small Series

We can design and produce prototypes and small batches for pre-series production. With a wide range of materials and a multitude of processes – and all this within a short production cycle.

Key Advantages

- Short production time

- High surface quality

- Versatile materials

- Our own production and cooperation with specialized partners

- Large components up to 4 m²

- In-house surface treatment and refinement/coating

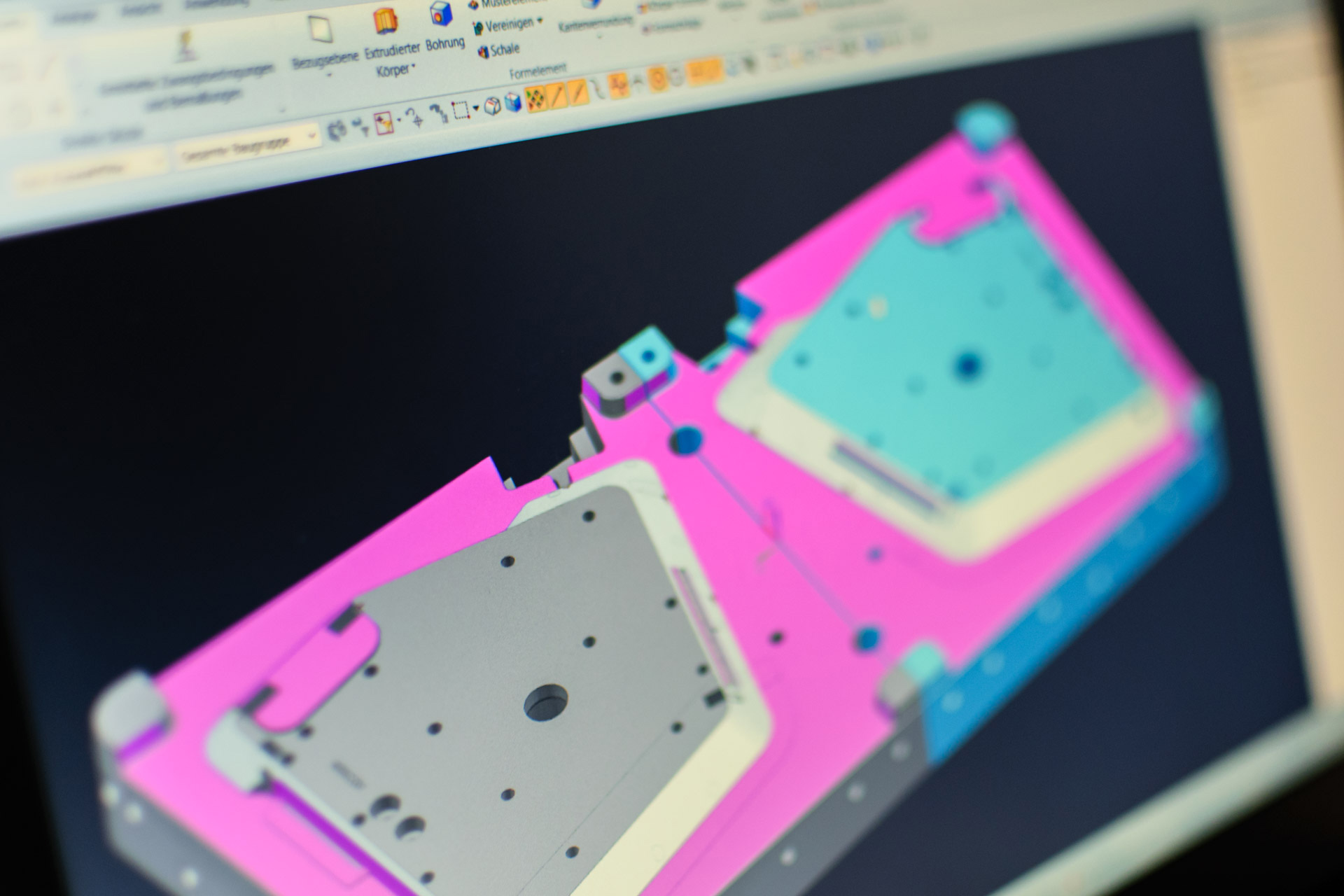

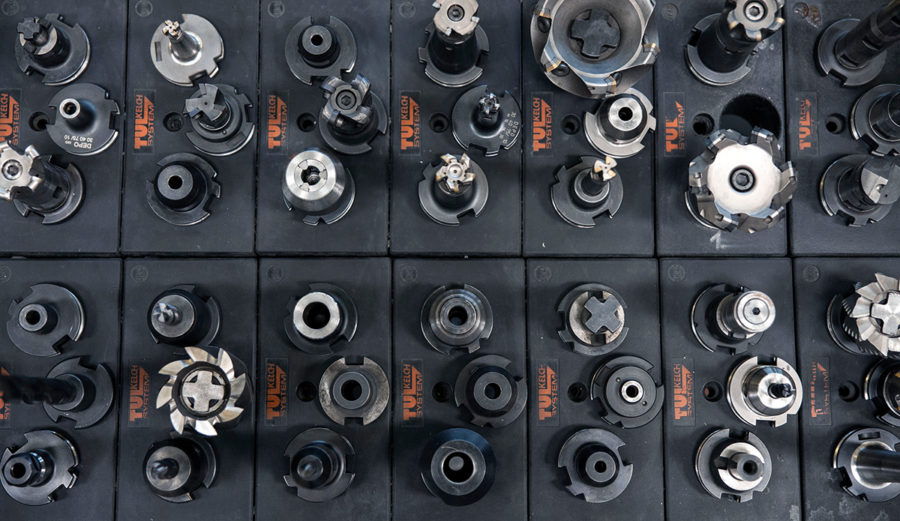

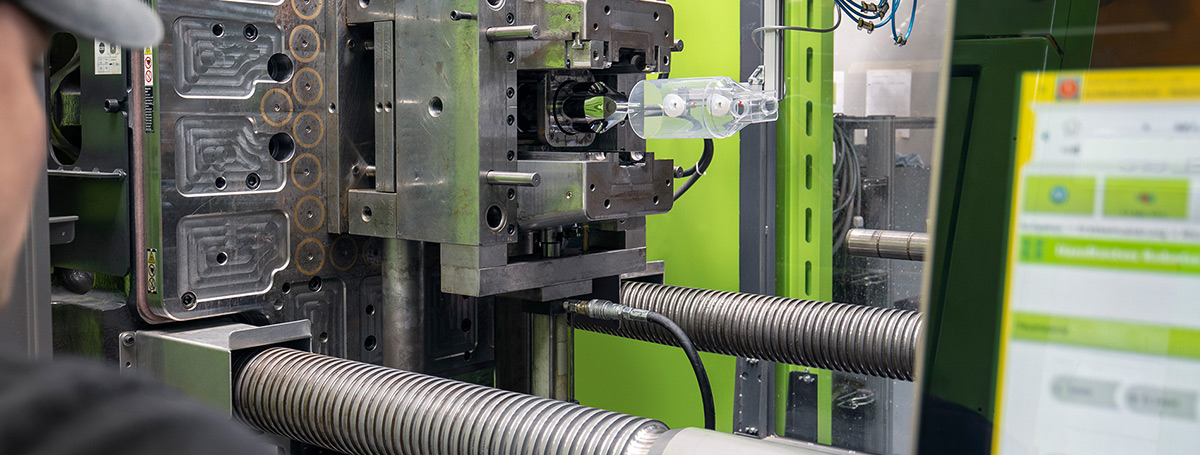

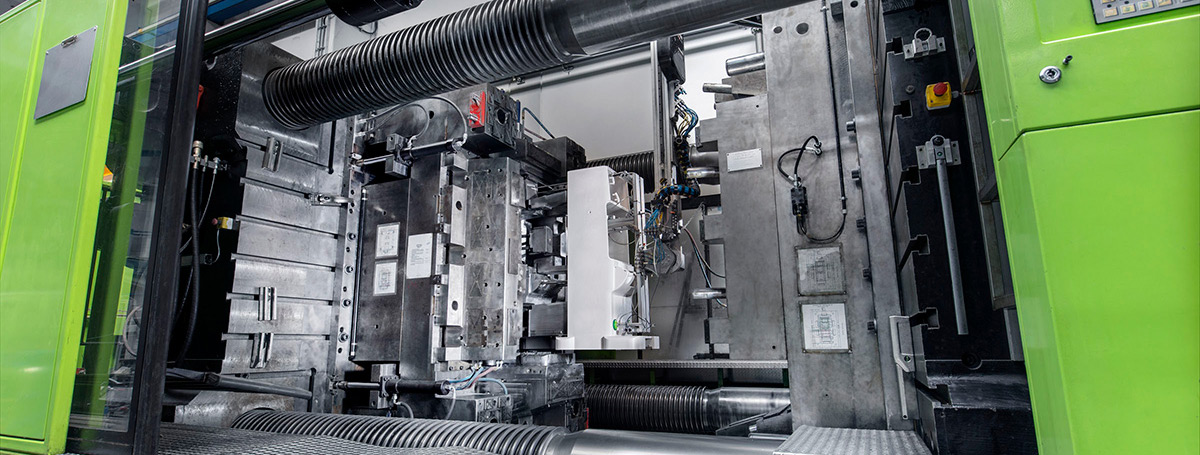

Mould Manufacturing

The design, construction and handling of large injection moulds are our speciality. No matter how complex the moulds are, we design the right tool for the job, realized and optimized by our worldwide tool partners under the best conditions. So that it meets German quality standards. After each production cycle, the mould is inspected, maintained and properly stored.

Key Advantages

- Production from low to high quantities

- Small and large components up to 4 m²

- Selection of several technical procedures

- Design, stability and surface quality

- Locking forces up to 32,000 kN in injection moulding

- Environmentally friendly use of recycled plastic and grist

- Injection moulds and handling of up to 60 tons of weight

- Development and construction according to German quality standards

- Processing of all common thermoplastics and customised material development

- Know-how and quality engineering in process and tool development

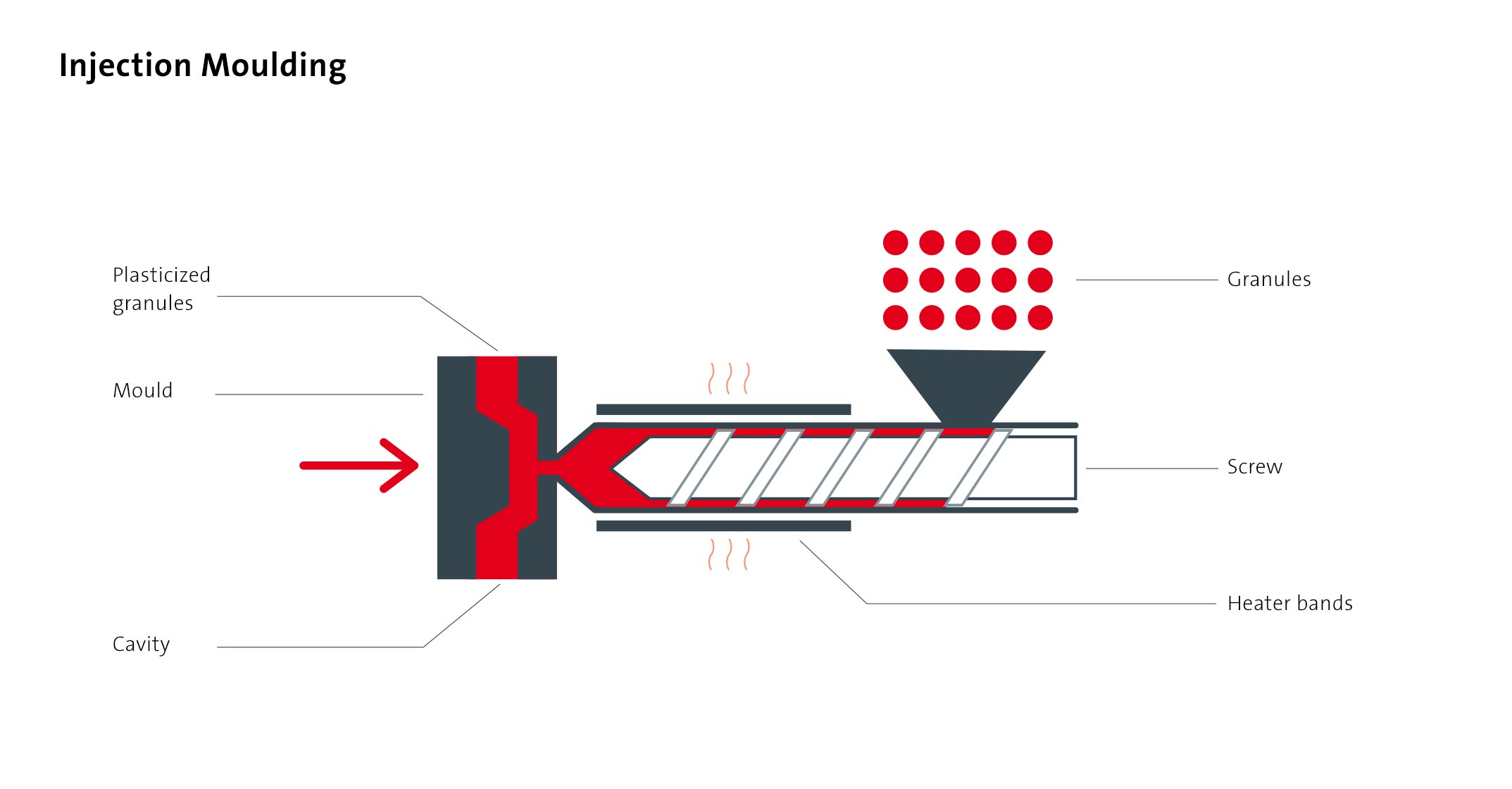

Injection Moulding

The Fried compact injection moulding process makes it possible to produce components of various shapes and sizes of the highest surface quality. For example, smooth and textured surfaces. It is particularly suitable for thin-walled components. Plastic granules are dispensed into the so-called snail by plasticizing and dosing, where they move towards the end of the snail. The friction heat generated by shearing melts the material.

The liquid melt is injected into the cavity via a nozzle. After the cooling phase the mould is ready. Thanks to hybrid technology, Fried offers the possibility of encapsulating external materials with plastic. A wide variety of materials such as ABS, PA, PC, PS, PE, PP, POM, ASA can be used. But also recyclable materials, fiberglass-reinforced granulates, FDA-listed materials and many more.

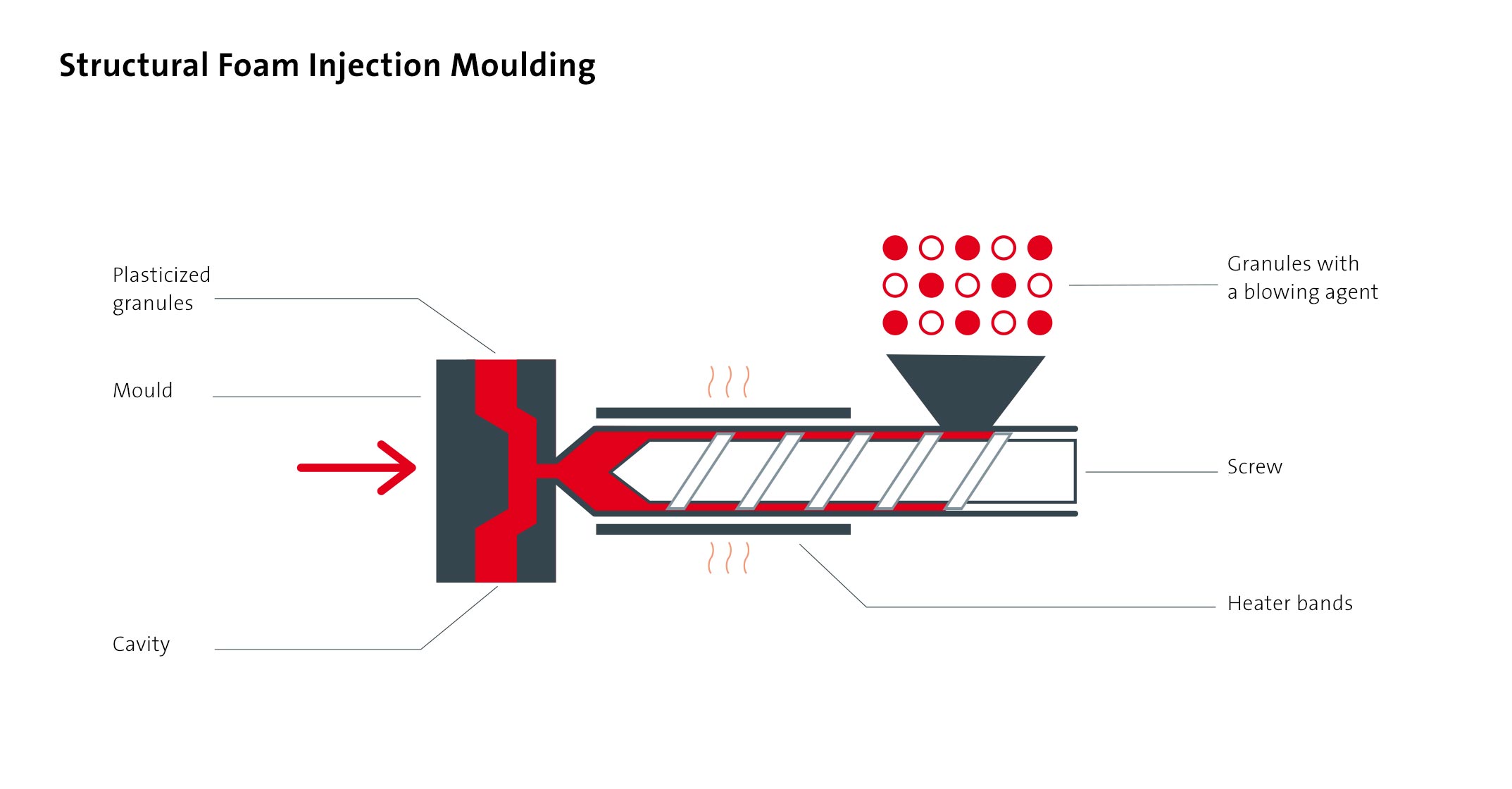

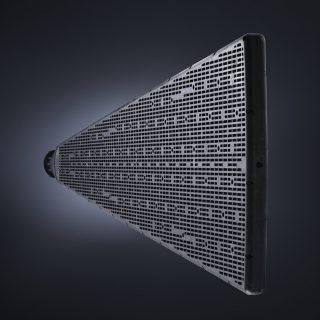

Structural Foam Injection Moulding

Structural foam injection moulding is recommended for the production of rigid components. Differences in wall thickness can be easily produced without any sink marks. The process ensures that additional pressure is created in the cavity by adding a blowing agent to the plastic granulate. The expansion process inside the component creates a foam structure and a compact, closed outer skin on the surface. Even complex components can be filled without any problems.

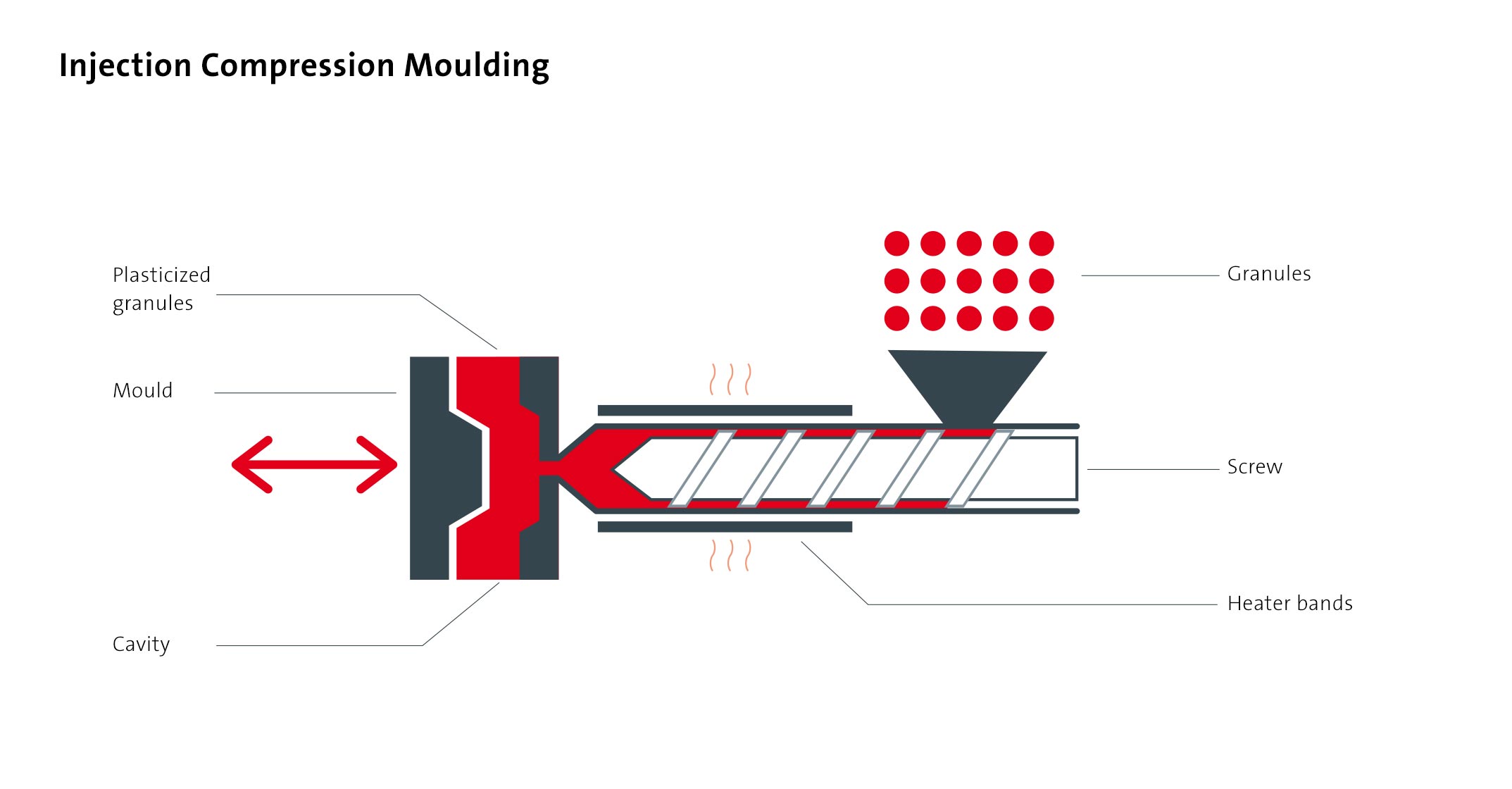

Injection Compression Moulding

Injection compression moulding is a special form of compact injection moulding. It enables the production of very large components with low locking forces. During the injection process, the mould cavity is left slightly open. This allows the melt to be pressed into a tool that is almost pressureless. It is only closed during the solidification process via the compression stroke. After the injection process, the component is brought into its final shape by the compression stroke.

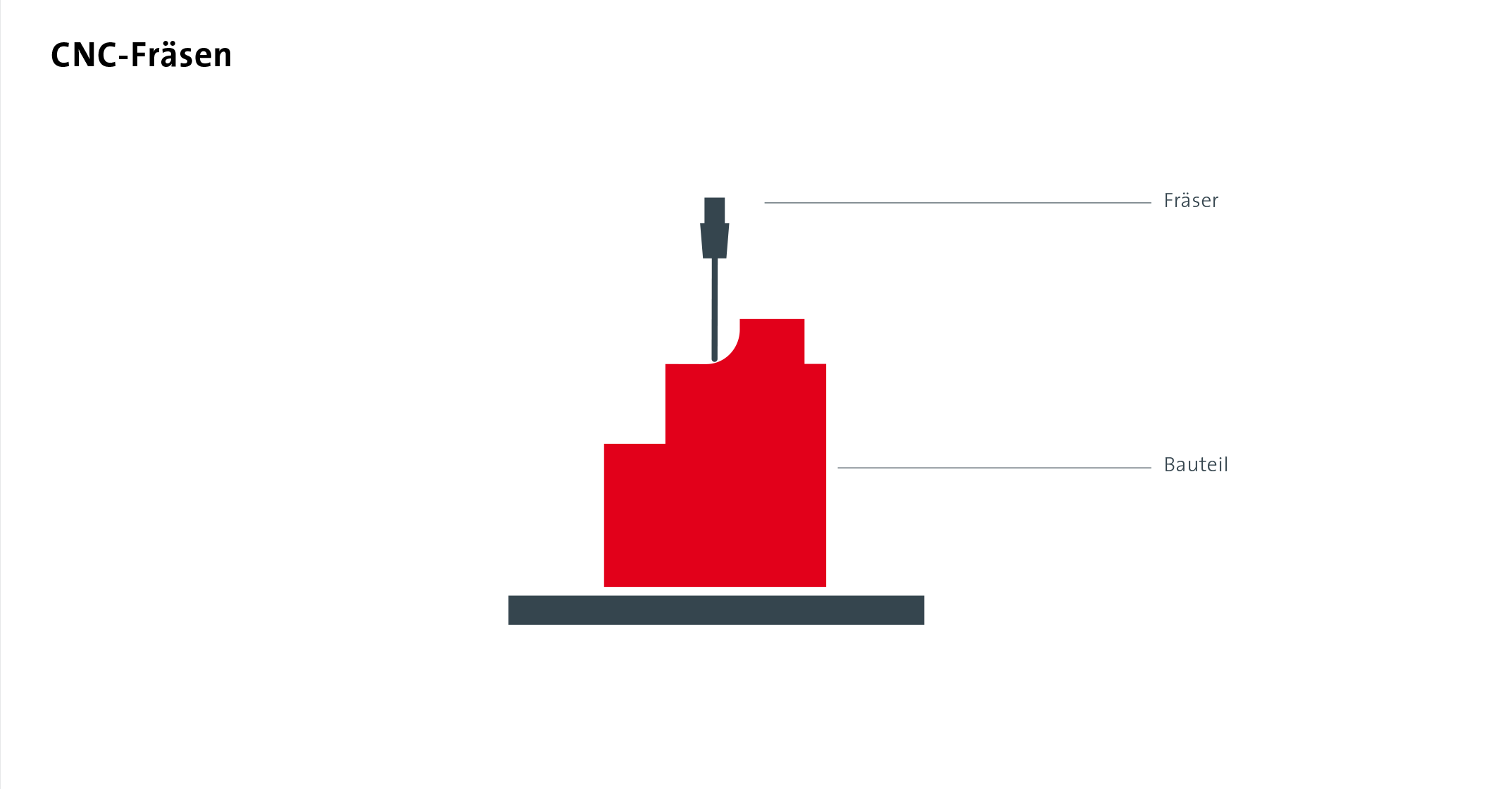

Machining

The machining of plastic components enables the fulfilment of special functions and the creation of follow-up processing options.