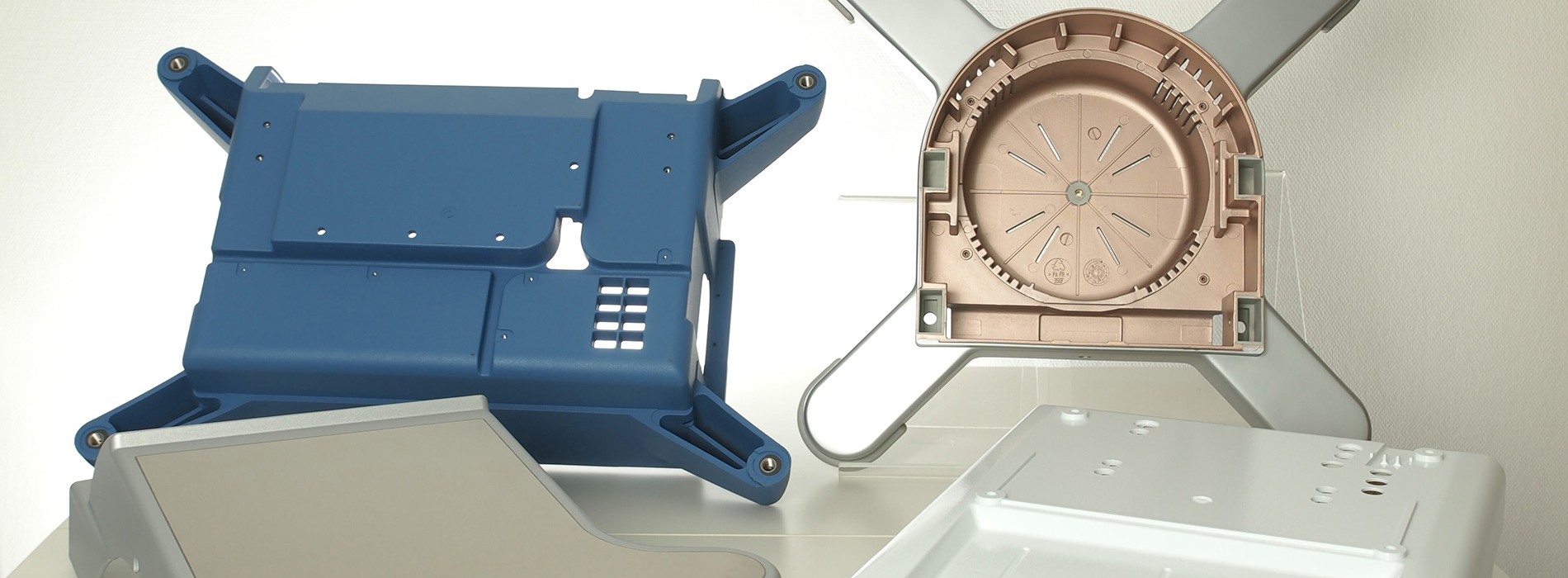

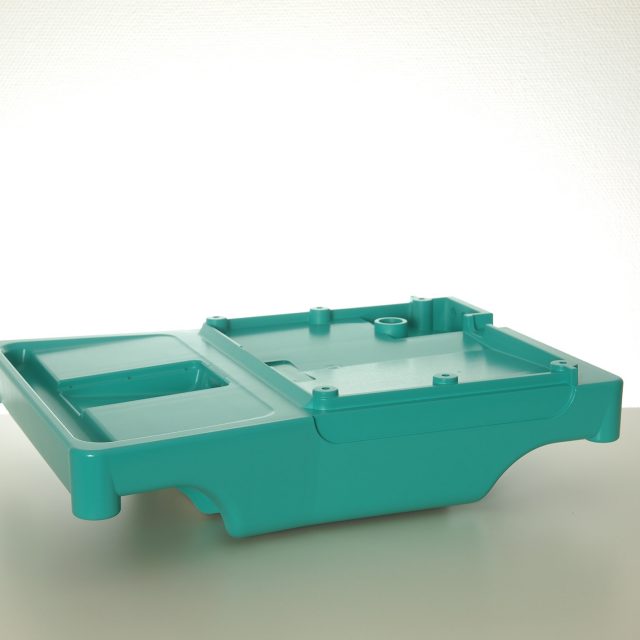

The combination of plastic production and coating makes Fried efficient and flexible. The experience of Fried Kunststofftechnik GmbH shows that this idea has proven itself in practice. For decades, we have specialised in large volume plastic injection moulded parts and have already manufactured equipment support for dialysis and mobile X-ray machines, as well as for surgery microscopes, operating tables or heart-lung pumping machines. In order to ensure the stability of these injection moulded elements, a glass fibre mixture is added to the plastics used in the equipment support. In structural foam injection moulding, the plastic-glass fibre composite is transformed into precisely fitting and dimensionally stable parts whose stability is comparable to that of metal. However, the injection moulded elements are resistant even when used in conditions where metal would corrode. This is particularly useful in medical technology, as the devices come into contact with the toughest cleaning agents.

For medical technology, we therefore also use specially developed coating systems, which are water-soluble for environmental reasons, but nevertheless are very robust chemically and physically. The equipment support receives this surface protection in the in-house coating shop at manual workstations or by coating robots.

In order to ensure EMC compatibility, Fried shields sensitive parts of the equipment support with a conductive copper coating, for example wherever the engines are installed. This means that there are no electromagnetic influences on the patient or on the sensitive measuring tools of the medical devices.

Your Keyword

- Large-volume device stands

- Injection moulding process

- Glass fibre reinforced plastics

- Special coatings for EMC protection

- Starting from a quantity of 200 pieces a year

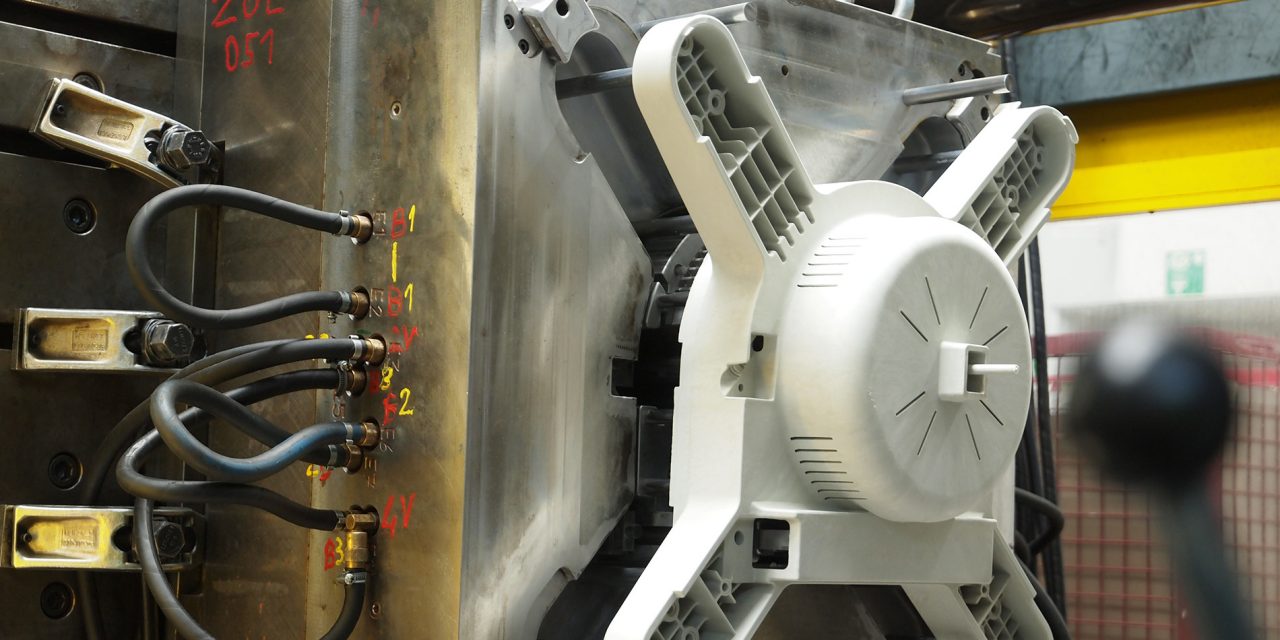

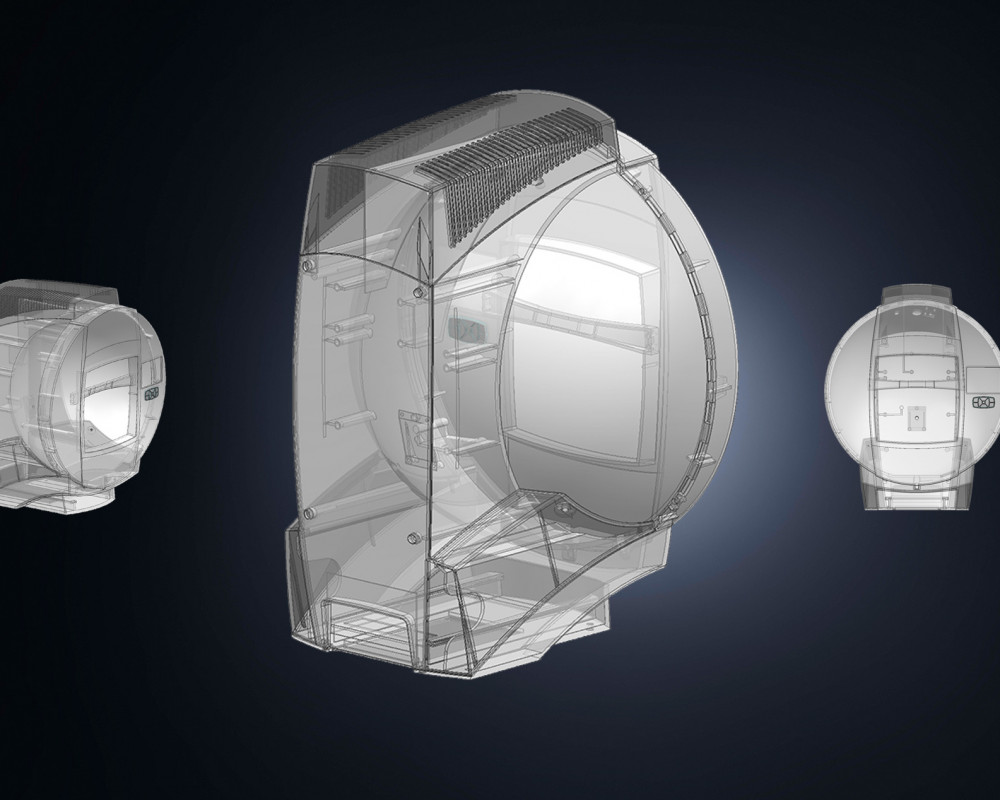

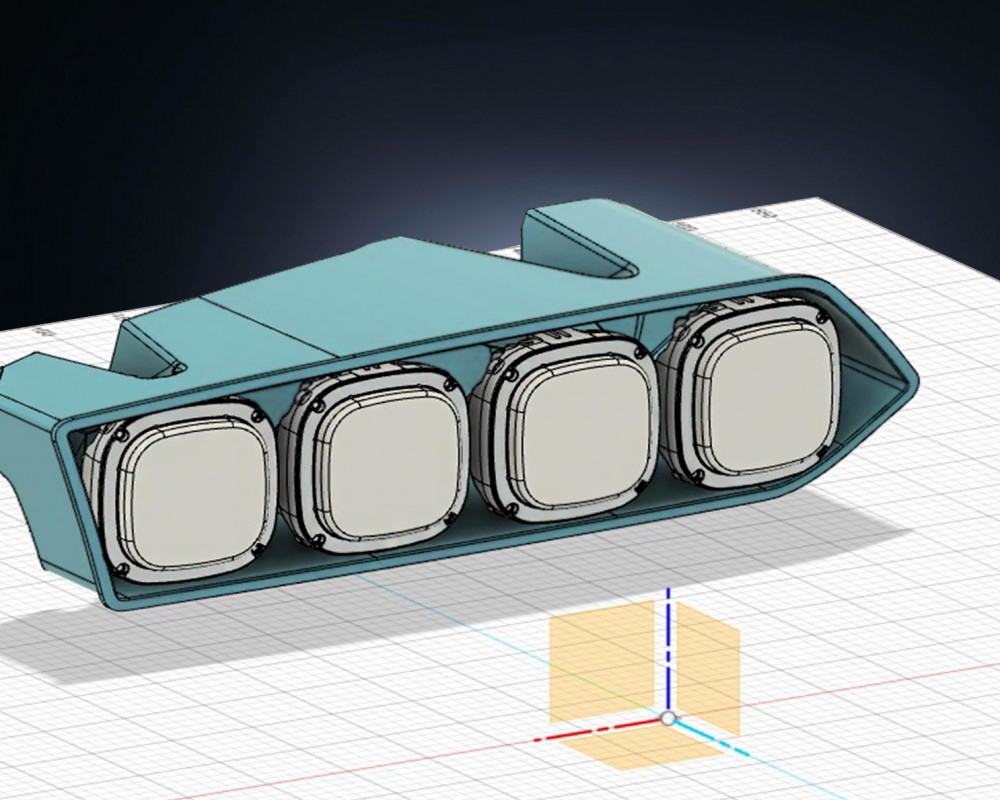

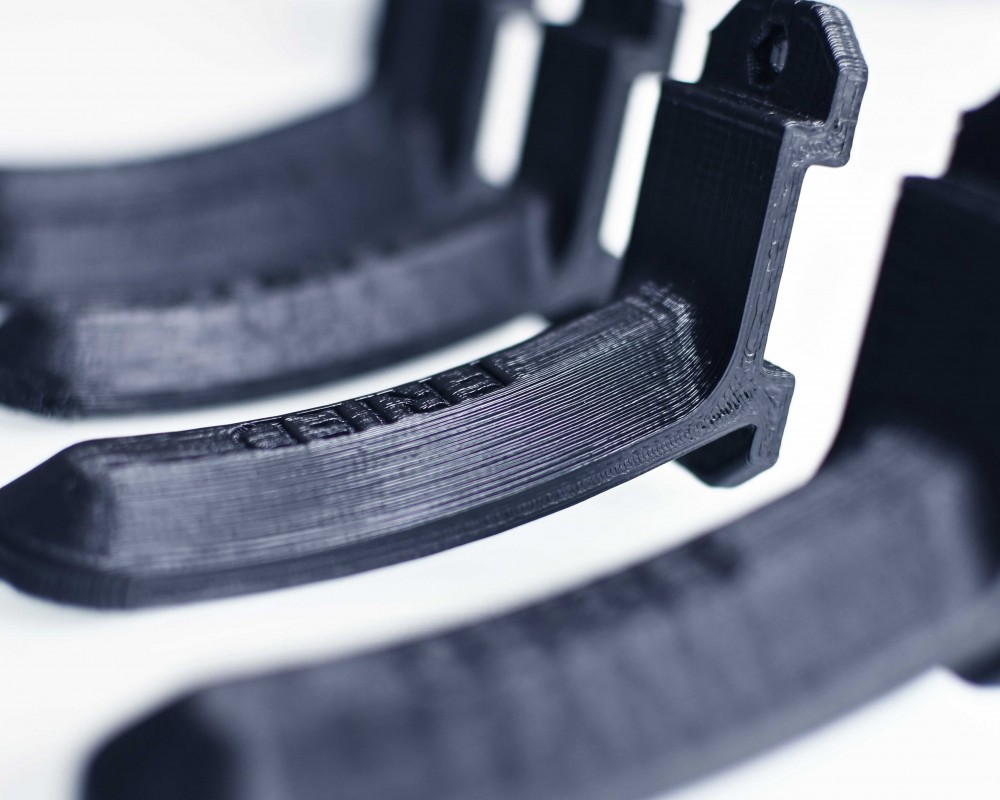

Many people are unaware that structural foam moulding is particularly suitable for largevolume parts. In training courses for developers and designers, these processes are explained and explored, for example the possibilities available for equipment supports. In such training courses and workshops, our Urbach-based company cooperates with universities or raw material manufacturers. In addition to technical details, this also involves the economic aspects of the process. Because the costs of tools are not only worthwhile for large batches: Even for small batches of around 200 units or more, the purchase costs pay for themselves quickly and promise a high level of cost-effectiveness. When developing such solutions, Fried’s mould specialists use modern 3D CAD systems, simulate the end product using FE methods and, if necessary, use rapid prototyping, for example, to produce a full-scale model before series production starts. All this is done in close cooperation with the client, whose design engineers are accompanied and supported.

Mould specification by the experts at Fried

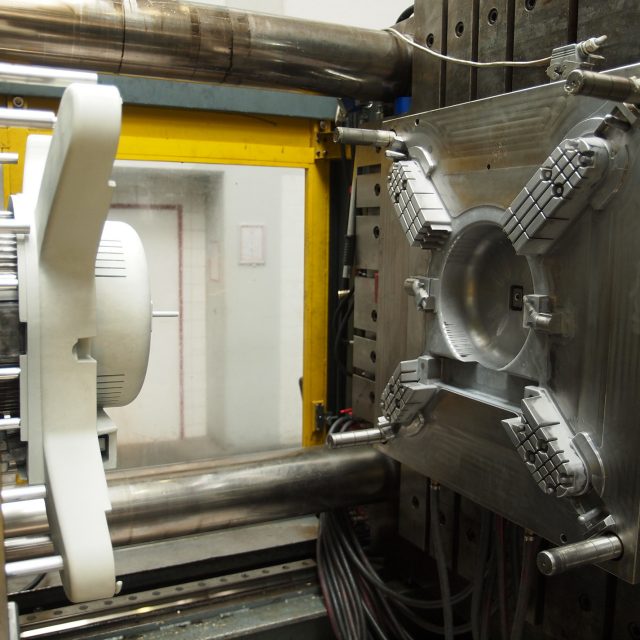

The engineers at Fried also determine the specifications for the mould, select the most suitable plastic with consideration of economic and technical aspects and calculate the flow behaviour of the materials. You decide which steel quality is required for the tool moulds and calculate parameters for subsequent production. The tools are manufactured according to these specifications by a team of specialists. For more than a thousand different moulds, the Urbach company maintains a warehouse in which the moulds are maintained and repaired if necessary by our own experts.

Powerful injection moulding machines with over 30,000 kN of locking force are used to manufacture the equipment support. The extremely high standards of the automotive industry are applied: Fried Kunststofftechnik GmbH is certified according to ISO 9001.

With this background, customers can also meet the respective standards on international markets, for example those of UL and FDA in the USA. Article excerpt from the magazine “Medizin & Technik” (medicine & technology)

Related Links

Structural Foam Injection Moulding