Charging Stations Made from Renewable Materials

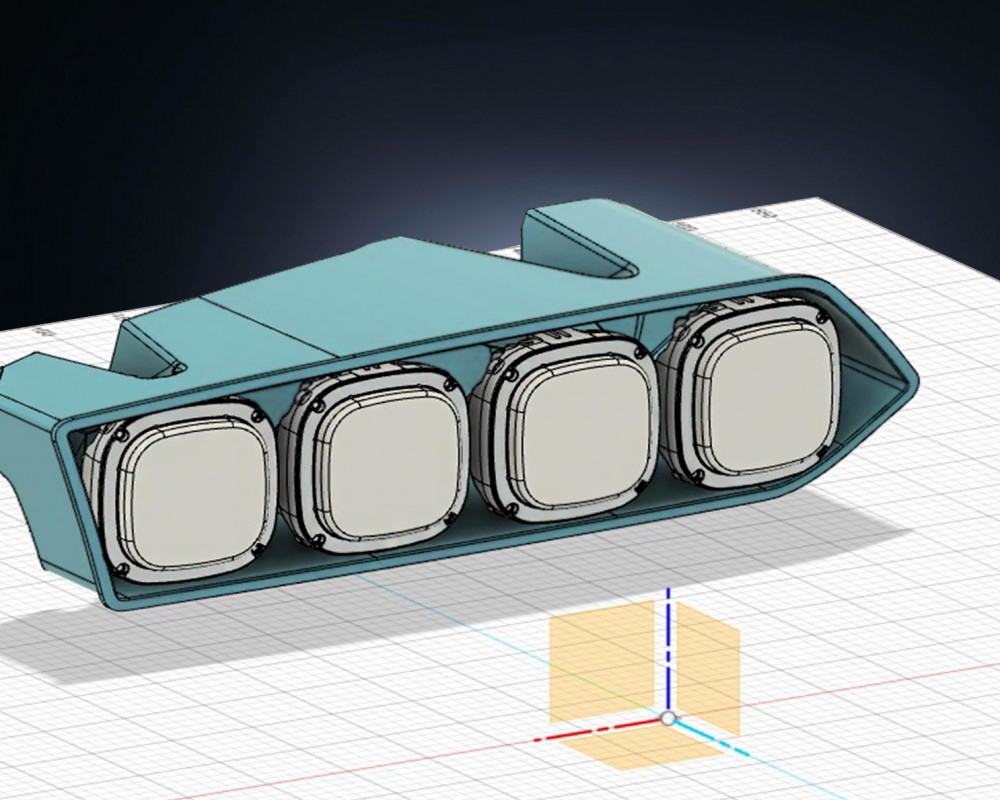

Fried is setting another milestone in sustainability: At the end of 2024, five CUBOS C44E charging stations were put into operation on the company premises of Fried Kunststofftechnik. These dual chargers allow employees to charge up to ten electric vehicles simultaneously in a 100% climate-friendly manner. Thanks to the company’s own photovoltaic system and the purchase of certified green electricity, Fried is making a significant contribution to environmentally friendly and resource-efficient mobility.

Sustainable Housings from In-House Production

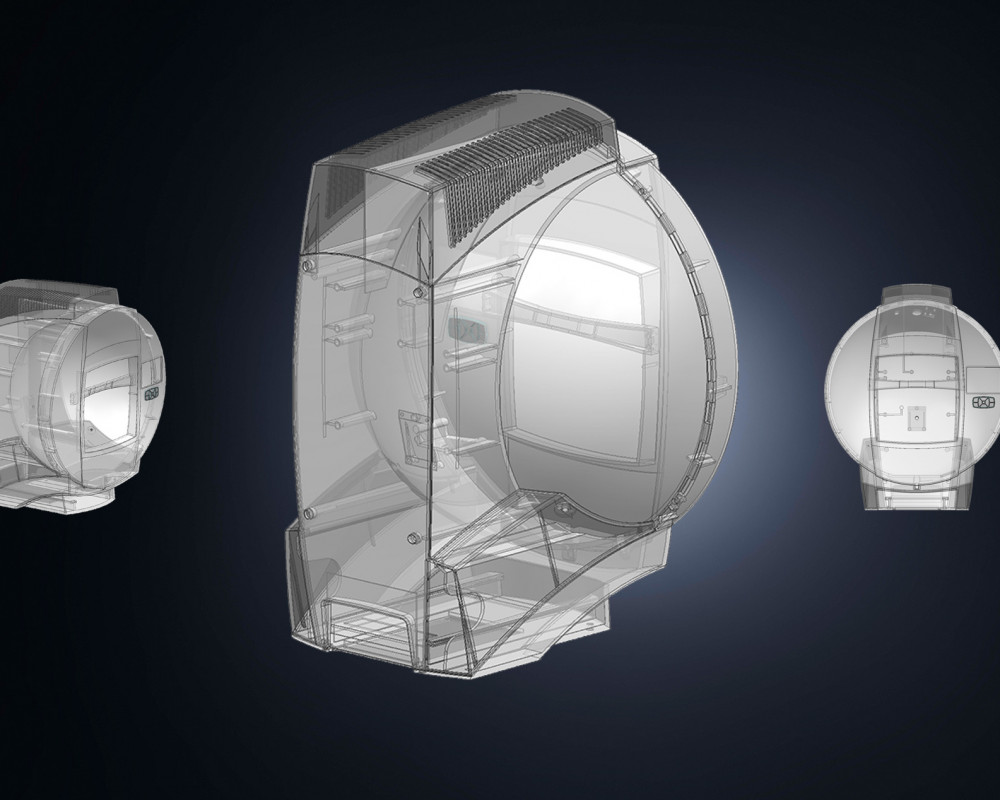

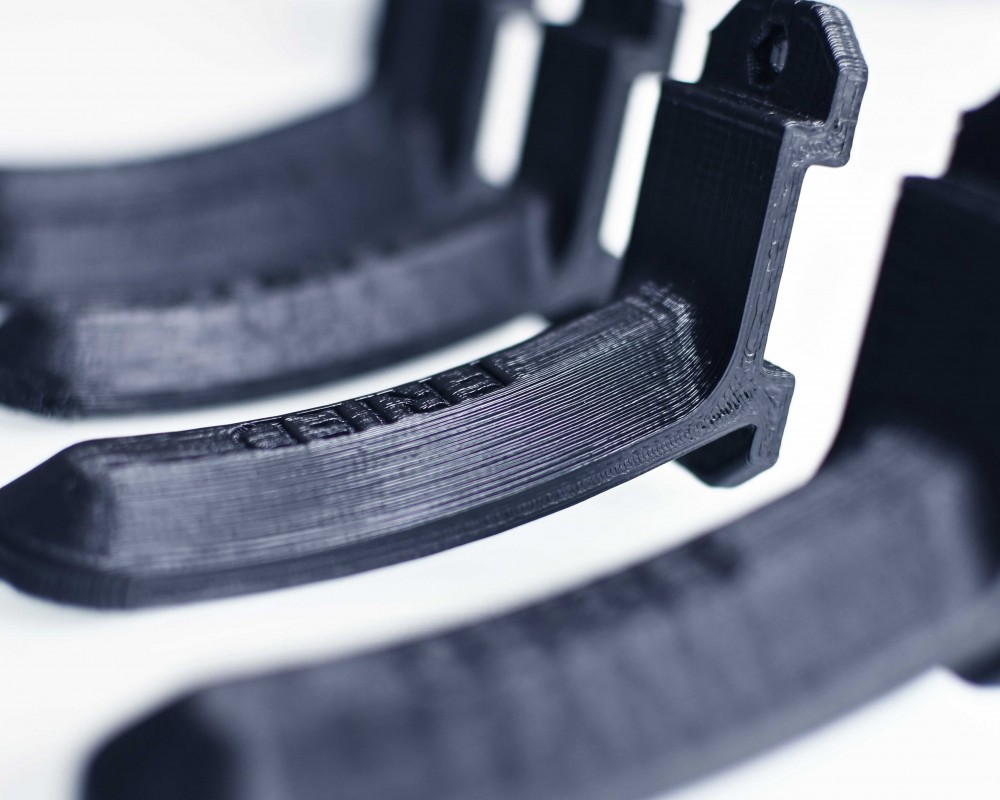

The innovative customer device, which Fried Kunststofftechnik first presented at the 2024 Fakuma trade fair in Friedrichshafen, has also convinced the Fried team with its sustainable concept. The series components, which have been in production since the end of 2024, were supplemented by an experiment. The wallbox was originally made from a special sustainable plastic material, Bayblend® RE from Covestro, which is produced from recycled vegetable oils. Fried’s experts took it a step further and used ARBOBLEND® – a material made entirely from renewable raw materials – for their own charging stations.

ARBOBLEND®: 100% Bio-Based Material

ARBOBLEND® is an innovative biocomposite material developed by Tecnaro GmbH and serves as a sustainable alternative to conventional petroleum-based plastics. The material consists of renewable raw materials such as lignin, starch, natural fibers, or biodegradable polymers and can be recyclable depending on the formulation. This actively contributes to reducing fossil resource consumption and promoting a circular economy. Thanks to its versatile processing properties, ARBOBLEND® is suitable for injection molding and can be tailored to specific mechanical, thermal, or optical requirements.

Currently, only five of these sustainable wallboxes are in use – all of them on the premises of Fried Kunststofftechnik. The customer is currently evaluating whether series production is feasible.

Exclusive Use for Employees

The new charging stations are intended exclusively for internal use. Employees at Fried Kunststofftechnik benefit from the opportunity to charge their electric vehicles at a low cost. Dedicated charging cards, a billing portal, and an online system for checking the real-time status of the charging stations are available. Thanks to their modular design and bolted components, the charging stations are also particularly durable and easy to maintain.

Related Links:

Wallbox Housing with a Focus on Sustainability

CUBOS C44E

TECNARO