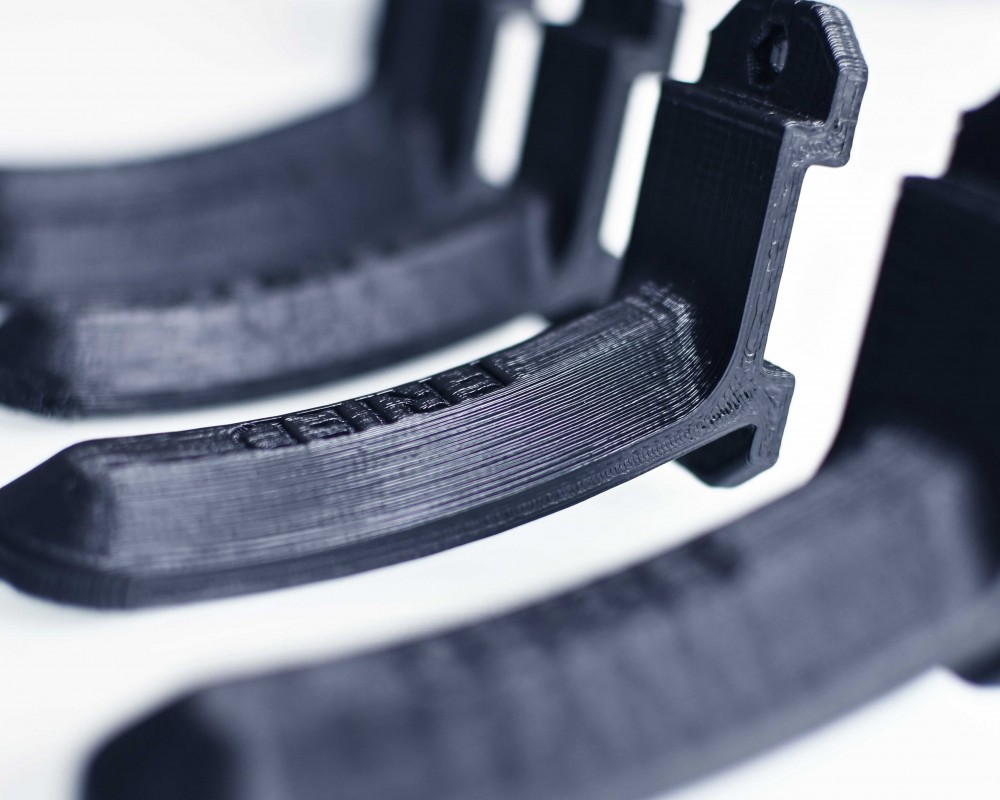

Mould Development at Fried

Fried Kunststofftechnik develops and designs injection moulds for the highest demands. The Fried experts advise customers and tool suppliers on part and tool design, so that a perfect form is created – with 100% guarantee.

Development

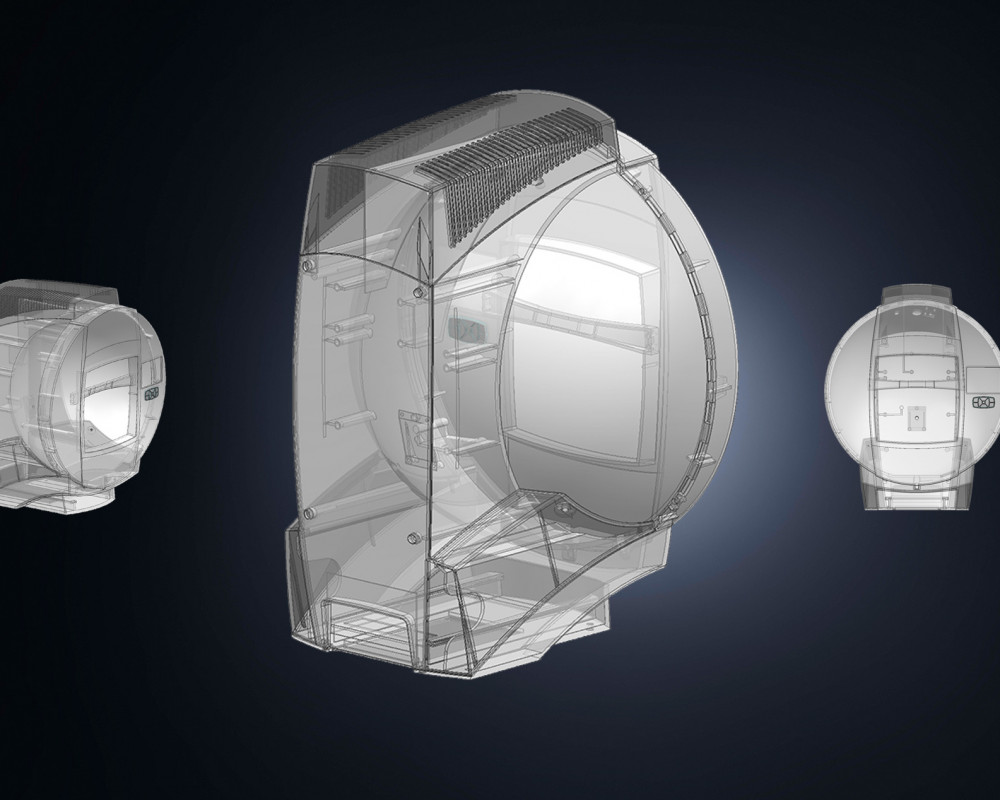

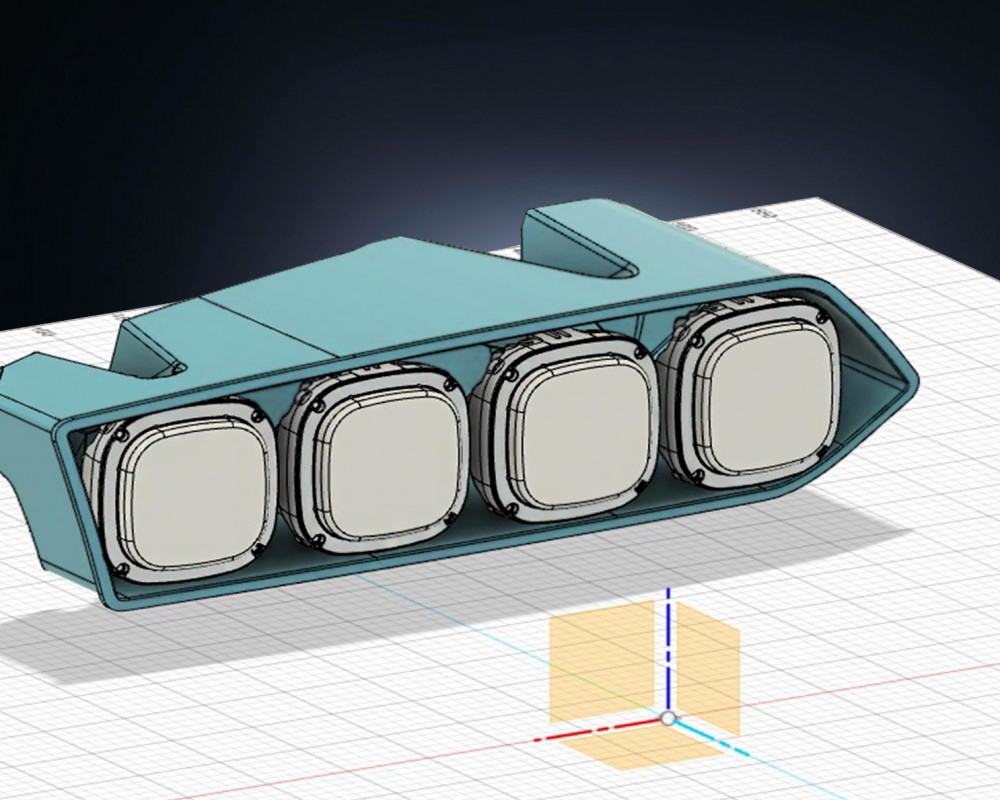

Where do you start and what should you consider for a new project? This is where Fried goes back to years of experience and a lot of know-how. Each tool is designed individually. However, there are many similarities in the construction of a moulding tool and in the development process, making the process as lean as possible.

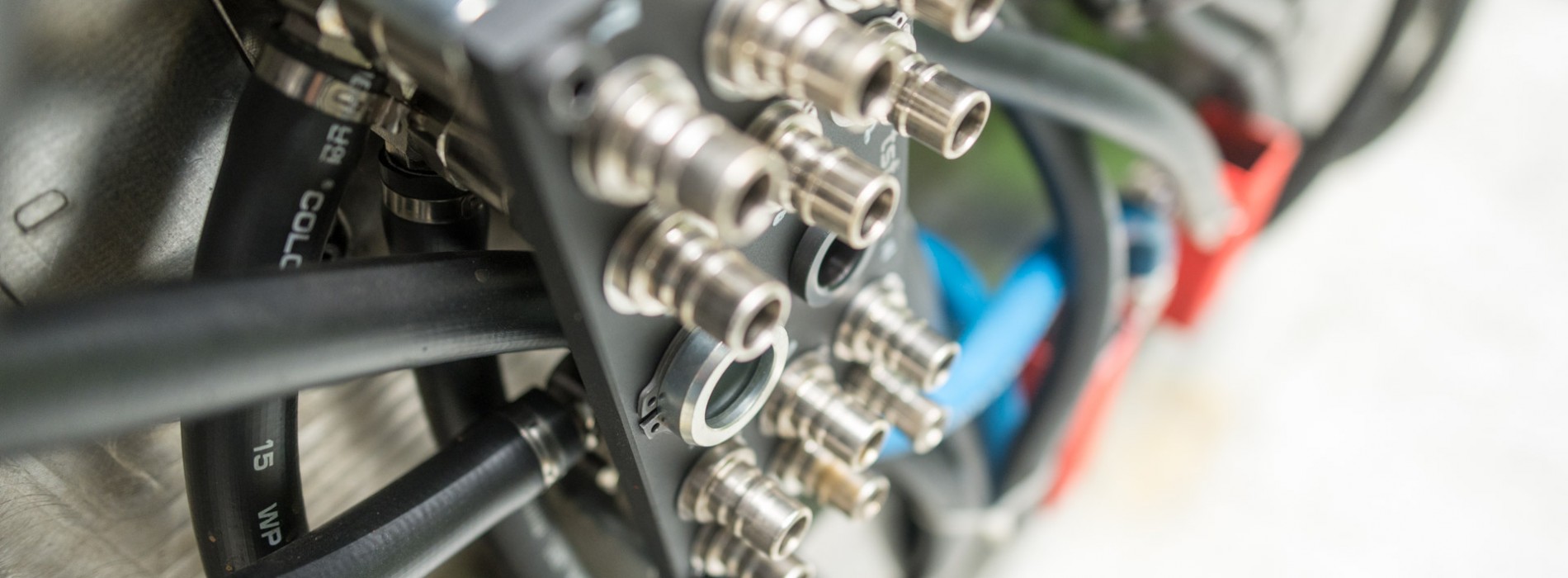

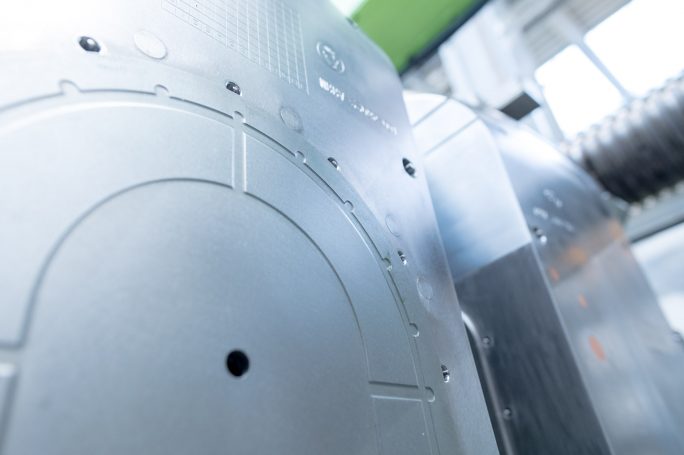

The material of the part, quantities and injection moulding processes play a decisive role in the tool development. After determining the visible side of the moulded part, the injection systems and ejector position should be defined. Further details of the tool will be determined in the next steps, such as mould plates that specify the contour of the part, hot and cold runner systems, clamping and insulation plans. In the case of complex parts, various add-ons also included, like special cooling elements.

Design

First, the customers’ product geometries, like shape slopes and outlines, will be checked. Fried Kunststofftechik has its own design guidelines, which must be taken into consideration by every tool supplier in the production process. The Fried specifications include, among other things, information on shrinkage, structure, coating and attachment to the injection molding machine. This guarantees the creation of a reliable and long-lasting tool.