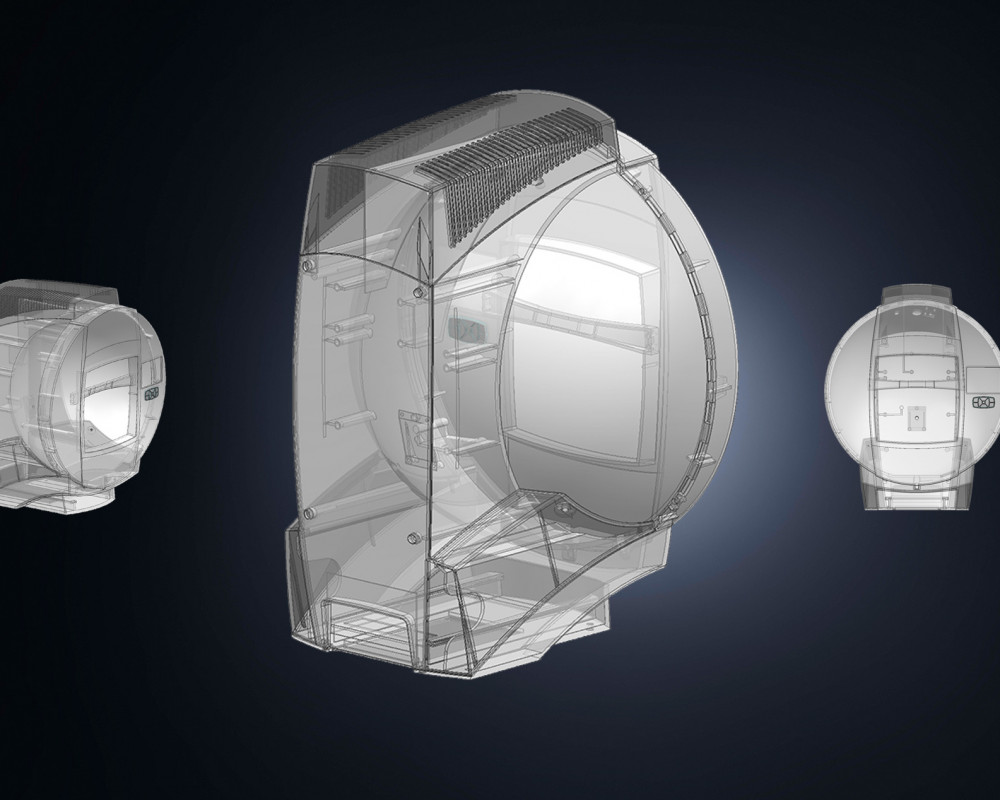

Question 3: How many housing parts are produced by Fried? Where are these used?

Dr. Hamilton: This CT is enclosed by a total of 21 housing parts. Eight of these essential parts are manufactured by Fried Kunststofftechnik. The development was particularly challenging since two different suppliers were involved. The parts produced by Fried Kunststofftechnik are crucial for the entire system. It’s not easy when you have two different partners who, while not using the same technology, are essentially competitors in manufacturing the housing parts. Nevertheless, the cooperation went very well. Fried was also very committed to making it work.

Question 4: How large are the quantities in this project?

Dr. Hamilton: As this is a high-end device, the quantities are still low, and we are still in the ramp-up phase, so the quantities do not yet match the targeted level. For the housing parts suppliers, it is a challenge to maintain high quality despite the low quantities.

Question 5: From which project phase was Fried allowed to support you as a partner, and in which processes?

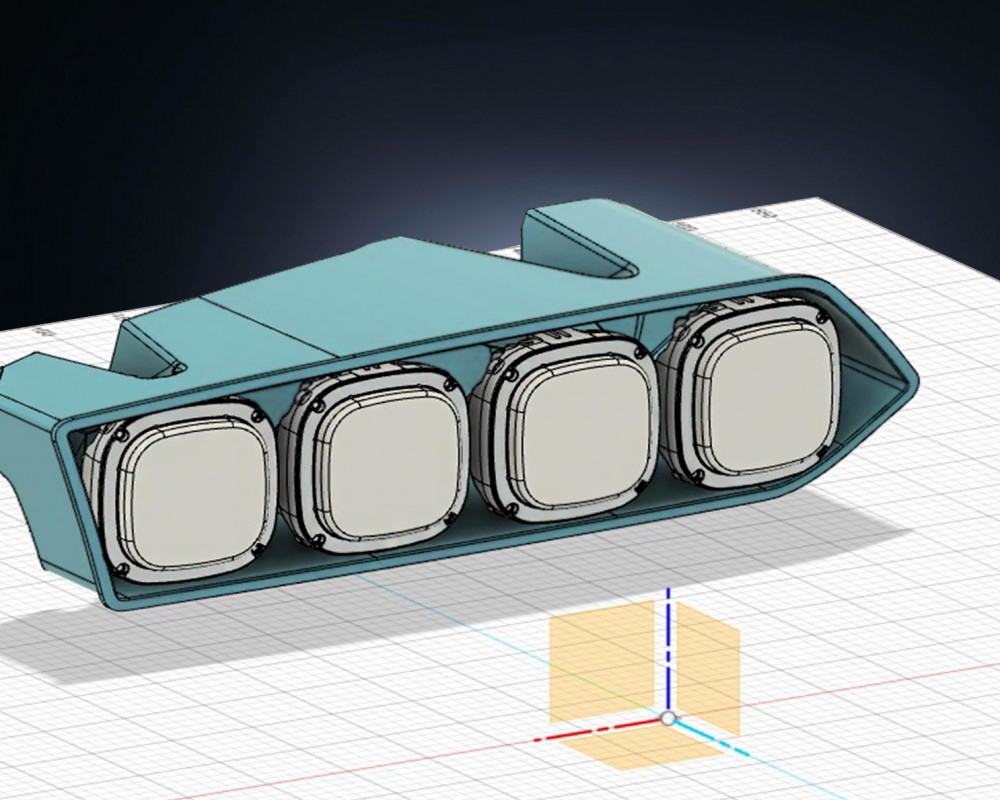

Dr. Hamilton: Fried Kunststofftechnik was a key partner in this project from the very beginning. Experts from Fried designed the parts for production during the design phase. Later in the project, a design change was made, which posed a challenge for both sides. We practically had to start from scratch, but Fried proved to be extremely committed and flexible.

Question 6: Were there any particular challenges in individual project phases?

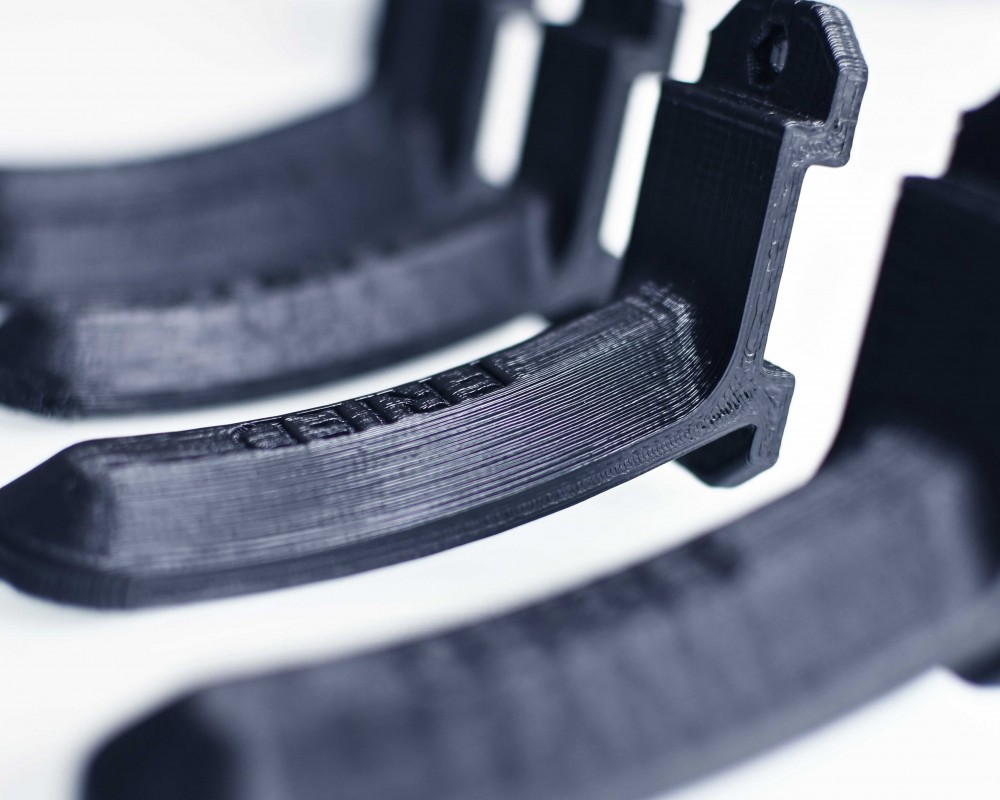

Dr. Hamilton: Indeed, there were some challenges, particularly due to the innovative design of the CT scanner. The exterior foil coating of the parts, which contains over 3,500 individual points, is extremely demanding in application and production, as even the smallest error is immediately visible. There were also challenges in tooling and prototype production that had to be overcome. The COVID-19 pandemic phase brought additional transport issues, especially regarding the transport of tools. Meanwhile, the parts are in series production, and we are working together with Fried on optimizations to keep the quality at the highest level.

Question 7: Are there specific industry-specific requirements that had to be considered in development, material selection, manufacturing, and assembly?

Dr. Hamilton: In the medical field and at Siemens Healthineers, the manufacturing quality requirements are particularly high. We use plastics that meet specific requirements for flame resistance and surface durability to comply with medical device standards.

Question 8: With which injection molding process are the components manufactured?

Dr. Hamilton: The components are mainly manufactured using the TSG injection molding process, while other parts are produced using the twin-sheet process. All housing parts are painted, and some are even multi-colored.

Question 9: What are Fried Kunststofftechnik’s tasks in the current collaboration?

Dr. Hamilton: Fried Kunststofftechnik currently plays a central role in optimizing the structure of the components to increase rigidity. Additional ribs are added to achieve an optimal joint pattern between the different housing parts. Additionally, they are responsible for production, painting, foil coating, pre-assembly work, and delivery and have implemented a specially developed packaging concept.

The realization of the Photon Counting CT project is not only a testament to technological excellence but also to the high flexibility and commitment of both teams. Close communication and joint overcoming of challenges have contributed to the product’s success.

Further Links:

Medical Devices & Healthcare at Fried

Siemens Healthineers: NAEOTOM Alpha® – the First Photon-counting Computed Tomography Scanner

Red Dot Award CT Scanner NAEOTOM Alpha

iF Design Award CT Scanner NAEOTOM Alpha