Sustainable and Innovative Transport Solution for Tractor Roofs

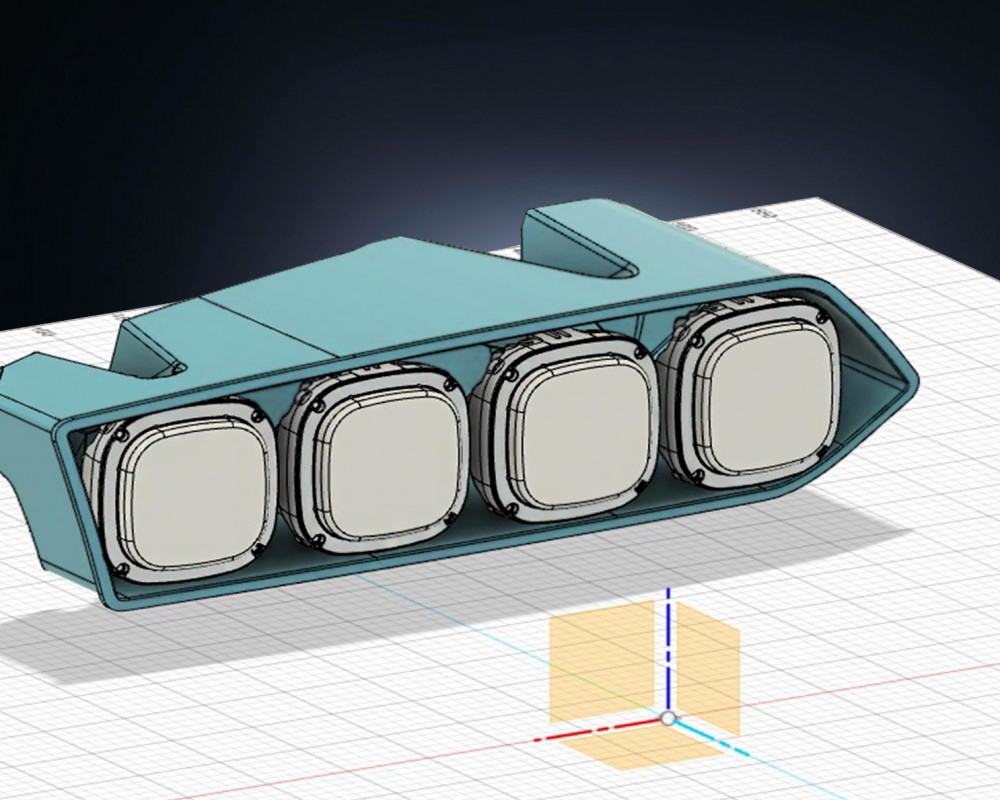

In collaboration with agricultural machinery manufacturer Fendt, Fried has developed a new logistics concept for the transportation of tractor roofs. With the aim of making logistics more efficient and cost-effective, the project involved designing specialized racks to facilitate the transport of thousands of tractor roofs per year, as well as further optimizing the delivery processes.

Aims and Challenges

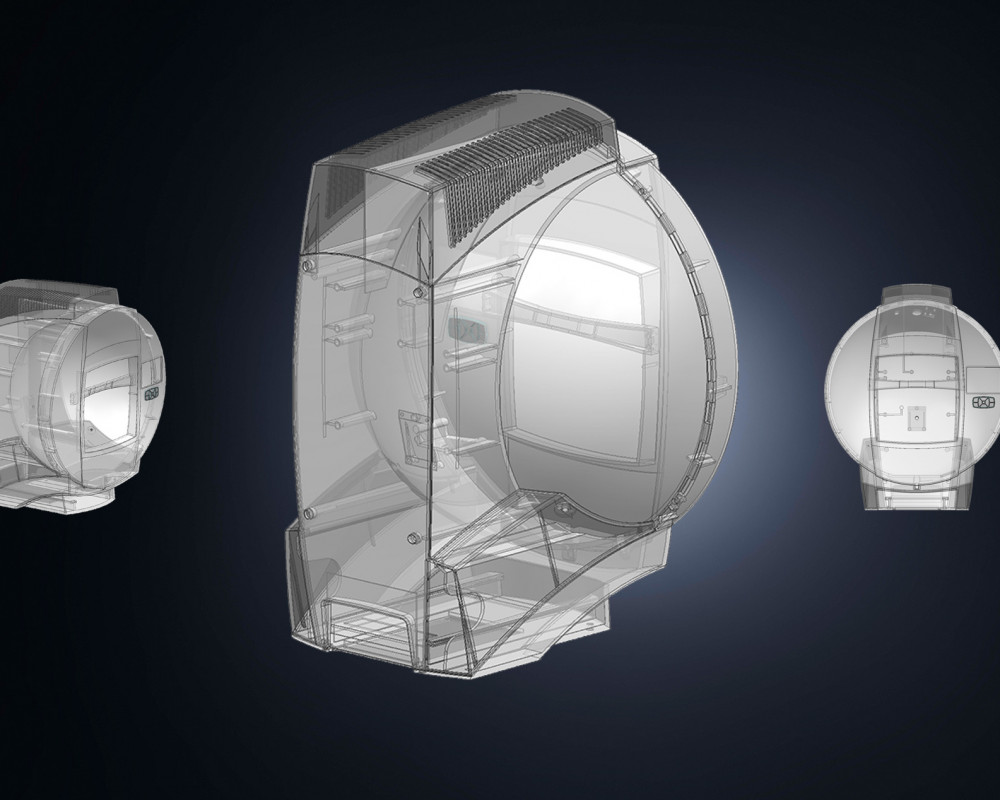

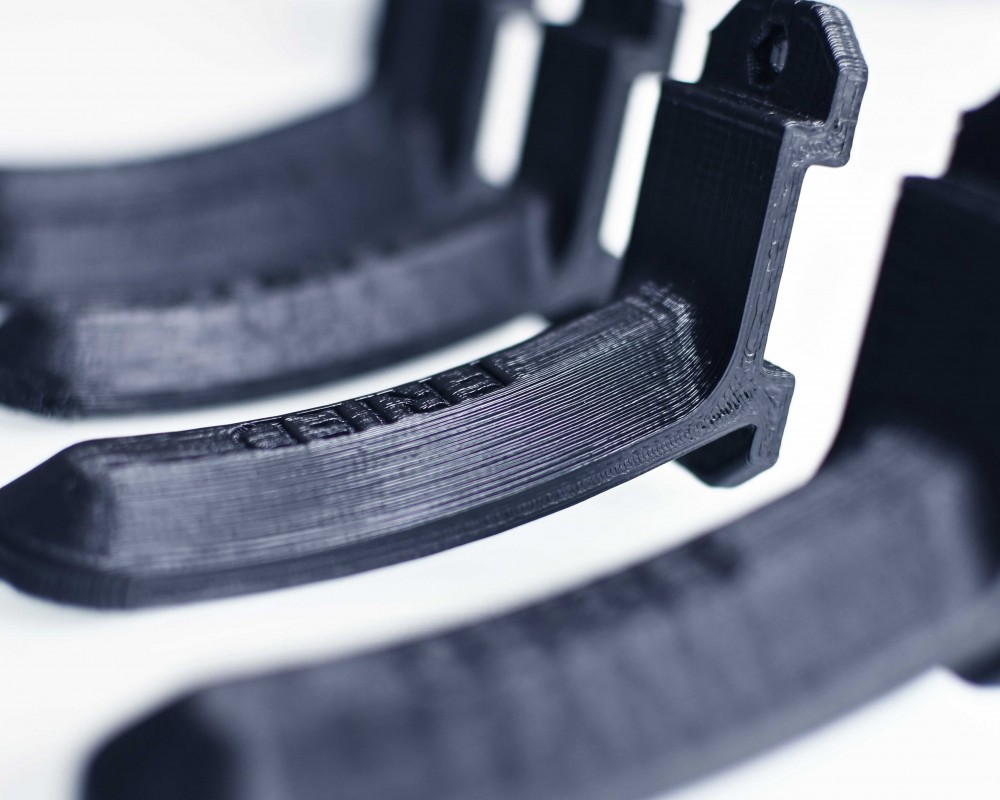

The project focused on the upper and lower parts of the roofs for the new generation of narrow gauge tractors in the Fendt 200 V/F/P Vario series. The goal was to develop an innovative transport concept for the efficient and safe delivery of tractor roofs. The biggest challenge was to design a rack that could carry two different variants of tractor roofs, which differed in shape and size. Additionally, the rack needed to be modular and space-saving to minimize logistical effort. Furthermore, since the roof parts significantly contribute to the vehicle’s final appearance, special attention was given to packaging and transporting the roofs in line with the high quality standards expected by customers.

Another key aspect for a sustainable and innovative transport solution was minimizing the use of additional packaging materials. “With older models, the parts had to be meticulously wrapped in plastic film and additionally secured to avoid damage,” explains logistics planner Fabian Herreiner, who, on behalf of Fendt, led the design of the transport racks and the development of the new logistics concept.